As demand for high-performance, durable sofa upholstery grows, more people are turning to Sofa Fabric Factory partners that specialize in warp knitting fabric. In recent years, manufacturers in the sofa and upholstery industry are not only looking at cost and appearance, but also new trends—such as sustainability, multifunctionality, and smart fabrics—in warp knitting materials.

1. Sustainable and Eco-Friendly Warp Knitting Fabric

One of the more significant trends is sustainability. More sofa fabric factories are integrating recycled fibers, bio-based yarns, or low-impact dyes into their warp knitting fabric lines.

The global warp knitted fabric market is seeing strong growth driven by innovation and increasing demand in various sectors—apparel, automotive, furniture included.

Consumers and brands are increasingly scrutinizing environmental impact—factories that can provide eco credentials (e.g. recycled PET, OEKO-TEX, low water usage) are more competitive.

How this trend shows up in practice:

Warp knits made with recycled polyester or post-industrial waste yarns

Use of water-saving dyeing and low-impact chemical finishing

Certifications like OEKO-TEX, GRS (Global Recycled Standard), or bluesign®

Transparent reporting of emissions, waste, resource consumption

A sofa fabric factory embracing these methods can market warp knitting fabric products as “green upholstery fabrics,” appealing to environmentally conscious consumers and brands.

2. Functional & Performance Warp Knitting Fabrics

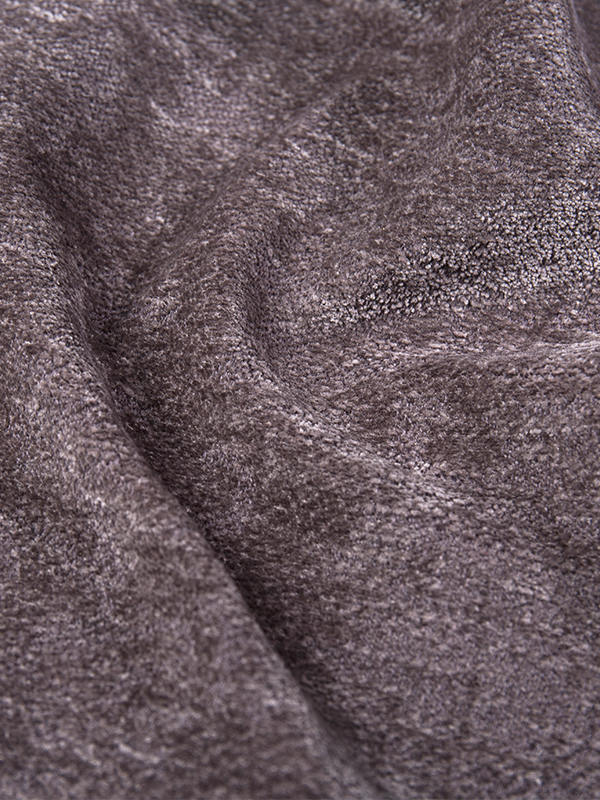

Another major trend is adding functional performance to warp knitting fabric. Beyond decorative use, sofa fabrics are now expected to handle everyday stresses and environmental exposures.

Key functions being integrated:

Stain / Spill resistance: Fabrics treated to repel liquids, resist stains, or facilitate cleaning

Antimicrobial / Antibacterial finishes: Especially in households with pets, kids, or in commercial settings

UV / Fade resistance: For sofas in sunlit spaces

High abrasion resistance: To prolong life under frequent use

Because sofa upholstery is a demanding environment, a sofa fabric factory is pushing warp knitting fabric lines that do double duty—nice appearance and high performance.

3. Hybrid Constructions & Composite Designs

Rather than simple warp knits, many factories combine warp knitting fabric with backing layers, laminates, or hybrid structures to improve strength and functionality.

For instance, backing with nonwoven or knitted support layers

Composite warp knitting + foam or stretch mesh for cushioning or shape retention

Spacer fabrics or 3D warp knits in certain zones to provide breathability or support

Use of lamination or coating (e.g. PU, micro-coating) to impart water resistance or durability

These hybrid designs allow sofa fabric factories to tailor fabric behavior—balancing stretch, support, aesthetics, and performance.

4. Customization & Digital / Smart Fabrics

Customization is a rising demand. Buyers want fabrics that match color palettes, textures, or even small-batch unique styles. Some advanced factories also explore smart fabrics.

Custom & digital trends:

Digital printing on warp knitting fabric for patterns, shading

Jacquard warp knitting with varying textures, designs in the same piece

Smart yarns / conductive fibers embedded for future “smart sofa” applications

Use of automation, software control, and tighter machine integration to shorten delivery times for custom warp knit orders

These trends push a sofa fabric factory to invest not just in machinery, but also in software, R&D teams, and flexible production lines.

By keeping up with these trends, a modern sofa fabric factory can offer advanced warp knitting fabric lines that appeal to discerning furniture makers and end users alike.

English

English 中文简体

中文简体 русский

русский عربى

عربى Español

Español