When furniture designers and manufacturers evaluate upholstery materials, they often visit a Sofa Fabric Factory to assess samples and technical specifications. They increasingly choose warp knitting fabric for sofas because of its unique combination of strength, flexibility, and aesthetics.

Structural Advantages of Warp Knitting Fabric

Dimensional Stability and Run/Fray Resistance

One of the inital things to appreciate is how warp knitting fabric behaves when cut and sewn. Unlike many fabrics that tend to unravel when edges are cut, warp knitting fabric resists runs and fraying due to its looped vertical structure. This means fewer defects at seams and better edge stability over time—critical in upholstery.

Additionally, warp-knitted fabrics maintain shape better under tension because the yarns are interlaced along the warp direction. This property ensures that cushions and panels don’t stretch unevenly or sag. On the technical side, warp knitting also allows three-dimensional constructions, wide widths, and efficient production.

Stretch, Recovery, and Conformability

Sofa cushions and frames often have complex curves or contours. Warp knitting fabric can be engineered with controlled stretch and recovery—so the fabric conforms gracefully to shapes without distorting over time. When the stretch is balanced, it ensures the fabric returns to its intended form, reducing puckering or sagging in upholstery.

Compared to woven fabrics that have limited stretch, warp knits offer more design freedom. In fact, many warp-knitted fabrics outperform other knit types in stretch/recovery and conformability.

Performance Benefits for Sofa Use

Abrasion & Pilling Resistance

Upholstery fabrics must stand up to repeated friction from sitting, moving, pets, or cleaning. Warp knitting fabric’s looped structure can be engineered to improve abrasion resistance and greatly reduce pilling. The knitted loops maintain integrity even under wear, which keeps sofas looking better for a longer time.

Backing, Composite Layers & Bonding

To further enhance performance, many sofa fabric factories combine warp knitting fabric with backings or composite layers. A knit backing (or warp knit + knit back) can give extra strength, dimensional stability, and support to the upholstery structure. Articles on upholstery backing note that knit backing helps prevent seam slippage, edge distortion, and shape loss over time.

Advanced bonding or laminating techniques—thermal lamination, ultrasonic welding, or laser bonding—can integrate protective films or layers into the fabric without compromising flexibility. These hybrid fabrics maintain softness while being robust against peeling and delamination.

Coated & Backing Applications (e.g. for Faux Leather Upholstery)

Warp knitting fabric also plays a key role when producing backed or coated upholstery fabrics (such as synthetic leather or bonded textiles). Warp-knitted backings are well-suited to receive coatings, thanks to their dimensional stability and slip resistance, which helps prevent delamination.

In such scenarios, the warp knit serves as the structural substrate, and the surface coating (PU, PVC, etc.) adds the desired finish, stain resistance, or aesthetic layer.

Finishing & Texture Options

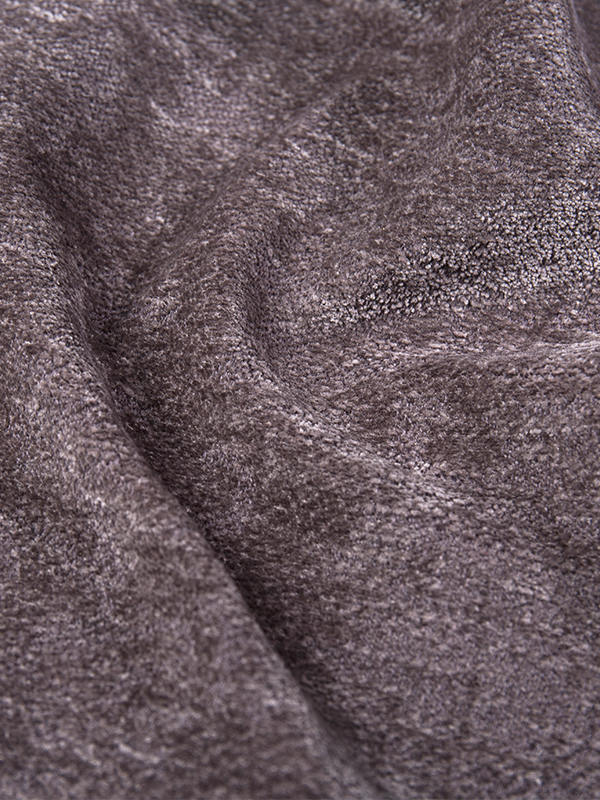

One of the exciting aspects for upholstery is the variety of textures and finishes you can achieve with warp knitting fabric:

Velvet, velour, plush: Warp-knitted velour/velvet constructions use long underlaps and careful shearing to create dense, upright piles that feel luxurious and maintain fiber alignment.

Brushed or embossed surfaces: Through mechanical finishing, pile raising, and brushing, warp-knitted fabrics can be made ultra-soft or with special tactile effects.

Stretch velvets / spandex blends: By introducing elastic yarns (e.g. spandex) in the base structure, warp-knitted velvet can accommodate more flexibility while preserving surface structure.

Digital printing & designs: Some sofa fabric factories integrate digital printing, embossing, or patterning on warp-knitted bases to meet customized aesthetic demands.

Thanks to warp knitting’s flexibility, decorating and finishing options are broad without compromising core performance.

English

English 中文简体

中文简体 русский

русский عربى

عربى Español

Español