When you search for a dependable Sofa Fabric Factory, one of the more common questions is: Which fabric is truly suitable for sofa upholstery? That’s where warp knitting fabric comes into play. As a textile manufacturer, we often guide clients toward warp-knitted options because of their balance of strength, flexibility, and aesthetics.

Key Criteria for Selecting Warp Knitting Fabric for Sofas

When evaluating warp knitting fabrics for sofa use, here are the major criteria to consider:

| Criterion | Why It Matters | What to Look For |

|---|---|---|

| Fabric Weight / GSM | Heavier fabrics generally offer greater durability | Look for mid-to-high GSM ranges (often 250–400 g/m² or more for upholstery) |

| Tensile / Tear Strength | The fabric must resist pulling or ripping under stress | Ask for lab test data (e.g. ASTM / ISO standard) |

| Stretch and Recovery | Upholstery must stretch moderately but recover without sag | Test by stretching in warp and weft directions and see if it returns cleanly |

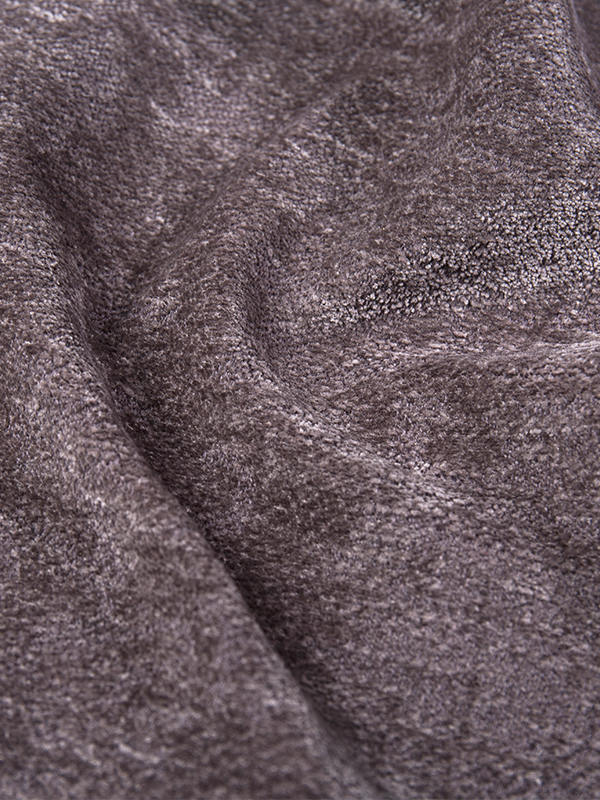

| Pile / Surface Texture | Texture affects feel, look, and maintenance | Velvet, chenille, and brushed warps are popular — check backing and pile stability |

| Colorfastness / Dye Stability | Fabric should resist fading from light, washing, or abrasion | Ask for ratings (e.g. ISO 105, etc.) from the producer |

| Abrasion Resistance / Martindale Cycles | Sofa surfaces see constant contact and friction | Look for high cycle counts (e.g. 25,000+ or more, depending on usage) |

| Backing / Composite Structure | Some warp-knitted fabrics include backings or laminates for reinforcement | Choose backings that add support without compromising flexibility |

These criteria are standard in many sofa fabric factories, and by asking for these specs you can compare different warp knitting fabric options effectively.

Steps to Evaluate and Test Warp Knitting Fabric

To ensure a warp knitting fabric is right for your sofa application, follow a testing process:

Obtain a Sample Swatch

Ask your sofa fabric factory to send a suitable size swatch (say 30 × 30 cm or more) so you can handle and inspect it.

Perform Hand Stretch / Recovery Test

Gently stretch in both warp (length) and weft (width) directions, then release and observe if the fabric returns to its original shape.

Conduct Visual Inspection Under Light

Look for any irregularities in the pile, weave, or backing. Check edges for fraying or weak loops.

Request Laboratory Testing Reports

Ask your supplier for test results on:

Tensile strength

Abrasion / Martindale cycles

Colorfastness (light, rub, wash)

Dimensional stability / shrinkage

Prototype or Trial Upholstery

Use the fabric on a small sofa or ottoman section to see real-world behavior — sagging, pilling, wear over weeks/months.

By following these steps — especially when working with a sofa fabric factory — you reduce the risk of fabric failure after production.

Common Pitfalls and How to Avoid Them

Even with warp knitting fabrics, pitfalls exist. Here are common ones and mitigation tips:

Too much stretch

Some warp knits may include elastic yarns (e.g. spandex) that over-stretch under use. Mitigate by balancing stretch yarn content and using stabilizing backings.

Weak backing or lamination

If the backing is too weak, the fabric may delaminate. Always check lamination quality and bonding processes.

Pile shedding

Fabrics with deep pile or loose construction may shed initially. Ask your sofa fabric factory about pre-brushing or pile locking processes.

Poor edge finishing

Edges that fray or run result to problems during cutting and sewing. Insist on proper finishing (e.g. edge locking) or selvage treatment.

Inconsistent batches

Variations between batches (dye lot, tension) can result to color or texture shifts. Always request batch consistency checks and keep swatches for reference.

Why Working with a Quality Sofa Fabric Factory Matters

A reliable sofa fabric factory can make or break your upholstery outcomes. Here's how:

Controlled processes: Better factories monitor yarn tension, knitting parameters, finishing, and QC to ensure consistency.

Variety and customization: They can supply different warp knitting fabric types — e.g. velvet warp knits, stretch velour, jacquard warps — to match styling needs.

Testing and certification: A mature factory can provide third-party test reports (e.g. ISO, ASTM, OEKO-TEX certificate) to back performance claims.

After-sales support: They can help correct a batch deviation, match color between lots, or tweak production parameters for improvement.

Thus, collaborating closely with the factory ensures your sofa fabric choices are not only aesthetic but reliable.

Choosing the right warp knitting fabric for sofa upholstery means more than picking the prettiest option — you must balance durability, stretch, weight, and surface texture. By working with a trusted sofa fabric factory, and rigorously testing samples via stretch, lab tests, and trial upholsteries, you can minimize risks and ensure long-lasting results.

English

English 中文简体

中文简体 русский

русский عربى

عربى Español

Español