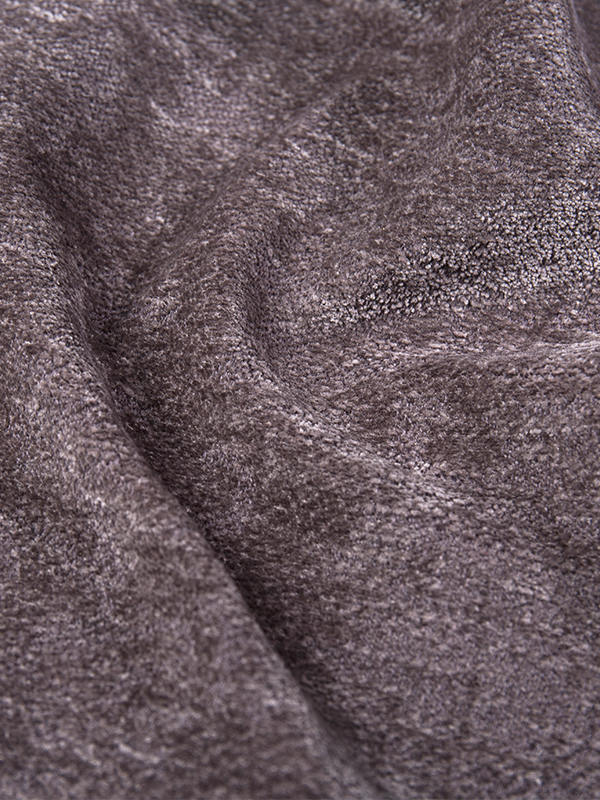

Holland velvet sofa fabric is renowned for its luxurious texture, making it a sought-after choice for high-end furniture upholstery. The fabric's soft, plush surface is created through a unique weaving process that incorporates a combination of thick and fine yarns. The result is a fabric with a rich, velvety feel that enhances the overall comfort of the sofa while contributing to its sophisticated appearance.

The texture of Holland velvet is primarily attributed to the dense, raised pile of fibers that are woven into the fabric. This pile can vary in length and density, with longer and denser fibers producing a more plush and luxurious feel. When the fabric is touched, it has a smooth, almost silky sensation, which makes it a favorite for upholstered pieces that require both comfort and elegance.

Additionally, the texture of Holland velvet sofa fabric can be influenced by the type of yarn used. Often, a blend of cotton and synthetic fibers like polyester is employed to achieve a balance of softness, durability, and resistance to wear. The yarns are carefully dyed and then woven into the fabric, allowing for both rich color and long-lasting texture.

Another notable feature of Holland velvet sofa fabric is its ability to reflect light in a way that adds depth and dimension to the piece. The smooth surface, combined with the intricate weave, allows light to play off the fabric, creating a soft sheen that enhances the overall aesthetic appeal. This makes it ideal for adding a touch of opulence to any living room or interior space.

The dyeing process of bronze lace fabric is a critical step in ensuring the fabric achieves its rich and vibrant hue. Bronze, a complex color that combines shades of brown, gold, and copper, is often chosen for its ability to add a touch of elegance to both formal and casual garments. The dyeing process begins with the preparation of the lace fabric, which is usually made from delicate fibers such as silk, cotton, or synthetic blends.

The step in the dyeing process is to thoroughly clean the fabric to remove any impurities or residues. This ensures that the dye adheres evenly to the fibers, preventing uneven coloration. Once the fabric is prepped, the dyeing process can begin. The dye used for bronze lace is typically a high-quality, acid-based dye for natural fibers or a disperse dye for synthetic materials. This choice of dye ensures that the bronze color is vibrant and long-lasting.

The fabric is then immersed in the dye bath, where the temperature and timing are carefully controlled. The dyeing temperature is crucial to achieving the shade of bronze. Too high of a temperature may an overly dark color, while too low a temperature can result in a dull or uneven finish. The fabric is allowed to absorb the dye for a specific period, after which it is carefully removed and rinsed to remove any excess dye.

Once rinsed, the lace fabric is treated with a fixative or mordant to help lock in the color. This ensures that the fabric retains its rich bronze hue even after multiple washes. The final step involves drying and finishing the lace, which may include light steaming or ironing to smooth out any wrinkles and maintain the fabric's delicate texture.

The dyeing process of bronze lace fabric is essential not only for achieving the desired color but also for ensuring that the fabric maintains its aesthetic appeal and durability. This careful process results in a stunning fabric that is ready to be used in a variety of high-end applications, such as evening wear, accessories, and home decor.

English

English 中文简体

中文简体 русский

русский عربى

عربى Español

Español