Silk screen printing fabric is a specialized textile used as the medium for transferring ink in the screen printing process. The material is designed to provide consistent ink flow, durability, and stability during repeated printing cycles. While the term “silk screen” originates from the use of natural silk fibers in early printing screens, modern silk screen printing fabric is made from synthetic materials such as polyester or nylon. These synthetic fibers offer dimensional stability, resistance to stretching, and the ability to withstand repeated exposure to inks and cleaning solutions.

The manufacturing process begins with the selection of high-quality filaments, which are drawn to uniform thickness. These filaments are then woven into a fine mesh using precision looms. The mesh count, which refers to the number of threads per inch, is a critical factor in determining the printing detail and ink deposit. Lower mesh counts are suited for printing bold designs with heavier ink coverage, while higher mesh counts are used for fine detail work.

Once woven, the silk screen printing fabric undergoes surface treatment to improve ink adhesion and reduce static. This may involve heat-setting the fabric to stabilize its dimensions, as well as applying a chemical coating to enhance ink flow. The finished material is then cut to size and mounted on screen printing frames, ready for stencil application and printing. By combining carefully selected materials with precise manufacturing techniques, silk screen printing fabric ensures accurate, repeatable results for both textile and non-textile printing projects.

The Invention of Warp Knit Polyester Print Velvet Fabric

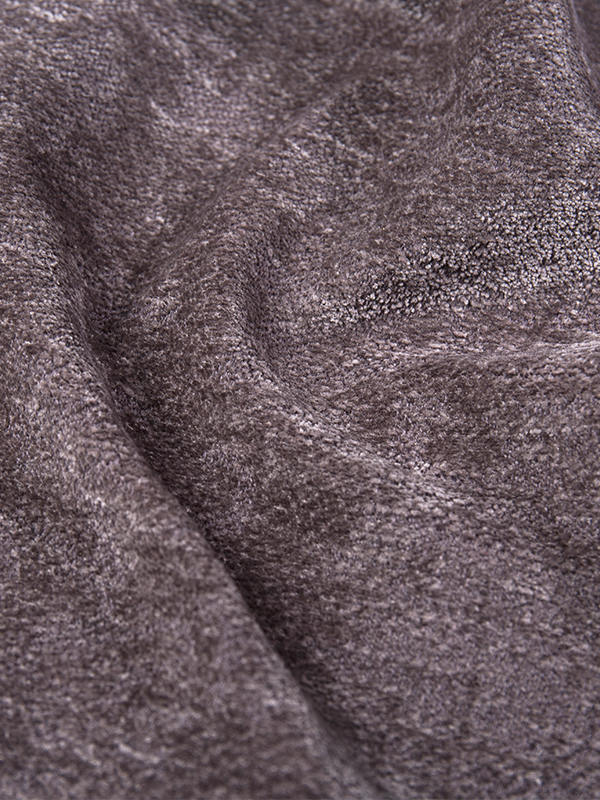

The invention of warp knit polyester print velvet fabric is rooted in advancements in both knitting technology and synthetic fiber production. Warp knitting, unlike weft knitting, involves yarns that run vertically through the fabric, creating a stable structure that resists fraying and distortion. This technique was adapted in the mid-20th century to produce pile fabrics, including velvet, by incorporating extra yarns that form loops on the surface.

The shift to polyester fibers played a key role in the development of warp knit polyester print velvet fabric. Polyester's strength, resilience, and ease of dyeing made it an ideal choice for a fabric that needed both durability and visual appeal. The knitting process involves feeding multiple sets of polyester yarns into guide bars that move in precise patterns, forming the ground structure and pile loops simultaneously. Once knitted, the pile is cut to create the soft, plush surface characteristic of velvet.

Printing technology further enhanced the appeal of this fabric. Rotary screen printing and later digital printing methods allowed for the application of intricate patterns and vibrant colors directly onto the velvet surface. The dense pile provides color saturation, producing rich, dimensional designs suitable for upholstery, apparel, and decorative items.

The combination of warp knitting technology, polyester's performance properties, and advanced printing methods resulted in a fabric that is both practical and aesthetically versatile. Its invention provided manufacturers with a cost-effective alternative to woven velvets while maintaining a luxurious appearance, widespread use in both residential and commercial applications.

English

English 中文简体

中文简体 русский

русский عربى

عربى Español

Español