Warp knitted polyester fabric and warp knitted spacer fabric share the same fundamental knitting method—yarns are interlaced in a warp direction on a knitting machine—but their construction, performance, and applications differ in important ways. Knowing how to identify each type is essential for manufacturers, designers, and end users who need specific material properties for their products.

Warp knitted polyester fabric is typically a flat, stable textile made entirely or primarily from polyester fibers. It can be produced in a wide range of weights and finishes, depending on the intended use. The key characteristics include good dimensional stability, moderate elasticity, and consistent surface appearance. When handling warp knitted polyester fabric, the structure feels compact, with minimal bulk, and it generally drapes well. The surface may range from smooth to textured, but it is essentially a single-layer construction. Common applications include sportswear, linings, home textiles, and industrial products where strength and low stretch are important.

Warp knitted spacer fabric, by contrast, is a three-dimensional textile made up of two outer layers connected by a network of pile yarns or monofilaments. This construction creates an internal space that allows for air circulation, cushioning, and impact absorption. When pressed between the fingers, warp knitted spacer fabric compresses and then returns to its original shape, demonstrating its resilience. The thickness can vary widely, from a few millimeters to several centimeters, depending on its function. This fabric is often used in footwear, seating, mattresses, and protective gear, where breathability and cushioning are required.

Visual inspection also provides clues. Warp knitted polyester fabric appears thin and uniform, while warp knitted spacer fabric shows a thicker profile and a mesh-like surface on at least one side. Holding the fabric against light can reveal the layered structure of spacer fabric, whereas standard warp knitted polyester fabric will appear more opaque and flat. By assessing the feel, thickness, and internal structure, it becomes clear which is which, ensuring the correct fabric is selected for the application.

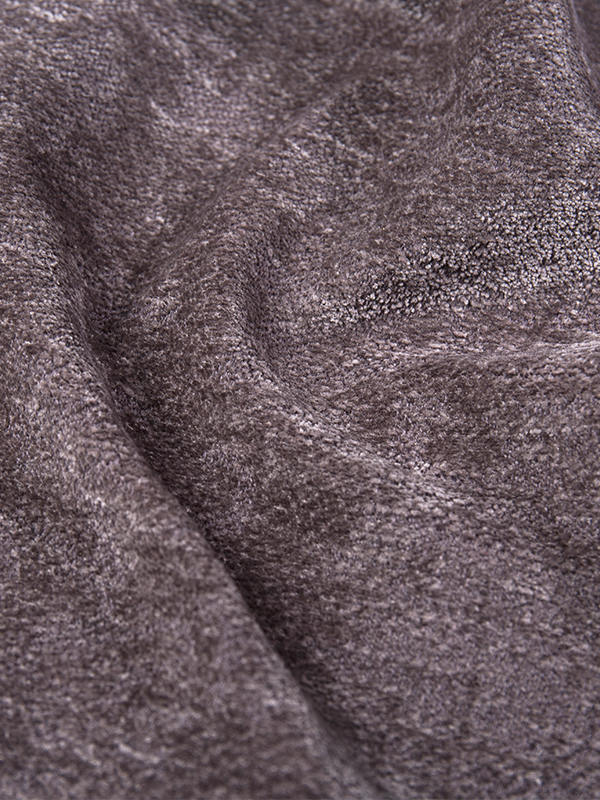

Warp knitted terry fabric combines the looped pile structure of terry cloth with the stability and efficiency of warp knitting. Its development was driven by the need for fabrics with absorbent qualities similar to woven terry, but with greater production speed and structural stability. Early terry fabrics were traditionally woven on specialized looms, creating loops on the surface for enhanced water absorption. However, as knitting technology advanced in the mid-20th century, engineers explored methods to replicate this looped effect through warp knitting machines.

By adapting the lapping movement of the guide bars and controlling yarn feed, manufacturers were able to create looped piles on one or both sides of a warp knitted base fabric. This innovation allowed for faster production rates and the ability to use a broader variety of fibers, including polyester blends, which improved drying time and durability compared to pure cotton woven terry. The introduction of synthetic yarns into warp knitted terry also made it more resistant to shrinkage and better suited for lightweight, quick-dry products.

Over time, warp knitted terry fabric found applications beyond traditional towels and bathrobes. It became a popular choice for sportswear, cleaning cloths, upholstery, and certain industrial uses where a combination of softness, absorbency, and structural strength was needed. The flexibility of warp knitting machines allowed for easy adaptation of loop height, density, and pattern, enabling customization for specific performance requirements.

Today, warp knitted terry fabric continues to evolve, with improvements in machine technology allowing for finer loops, more complex patterns, and sustainable fiber integration. Its history reflects a broader trend in textiles: combining traditional performance characteristics with modern production efficiency to meet diverse market needs.

English

English 中文简体

中文简体 русский

русский عربى

عربى Español

Español