Warp knitting is a highly efficient textile manufacturing method that produces fabrics with dimensional stability, versatility, and design potential. In the case of Warp Knitting Velvet Print Upholstery Fabric, the process involves creating loops in a longitudinal direction using multiple yarns fed from warp beams. This method allows for a smooth, dense surface with intricate printed designs, making it ideal for upholstery applications where both durability and visual appeal are important.

The loop formation process of Warp Knitting Velvet Print Upholstery Fabric begins with yarn preparation. Filament yarns or spun yarns, often made from polyester or a polyester blend, are selected for their strength, dye affinity, and soft texture. Multiple yarn packages are mounted on the warp beams, ensuring consistent yarn tension. For velvet upholstery fabric, the yarn type and denier are chosen to achieve the desired pile height and surface softness.

Once the yarns are in place, the knitting machine's guide bars control yarn movement to form the fabric structure. In Warp Knitting Velvet Print Upholstery Fabric, the set of yarns creates the base ground loops, while additional guide bars feed the pile yarns that will later form the velvet surface. The needles move up and down, capturing yarns into loops in a continuous motion. This results in a stable, non-fraying fabric foundation that supports the pile layer.

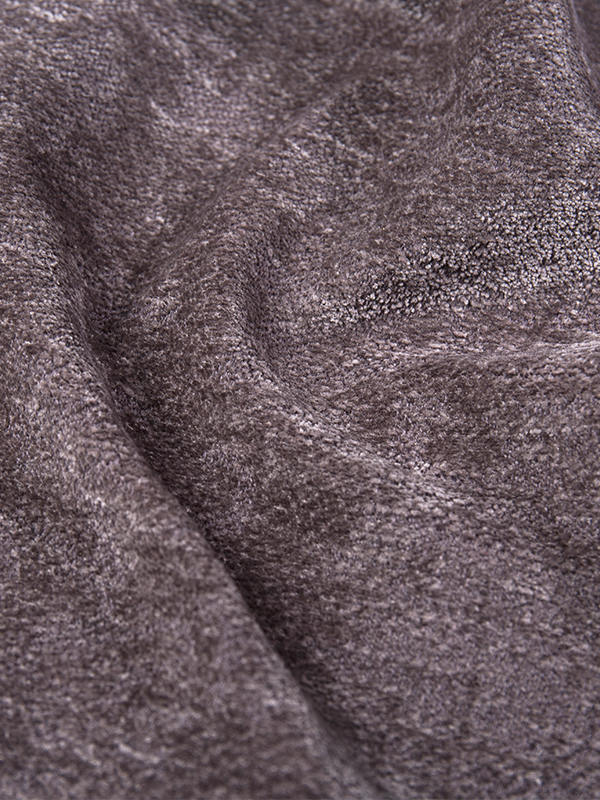

The pile formation stage is crucial for Warp Knitting Velvet Print Upholstery Fabric. Pile yarns are looped above the fabric surface and can be cut or left uncut, depending on the desired velvet effect. Cut pile produces the soft, plush texture typical of velvet, while uncut pile gives a different tactile and visual appearance. In upholstery fabrics, cut pile is preferred for its luxurious feel and dense coverage.

After loop formation, Warp Knitting Velvet Print Upholstery Fabric undergoes shearing to ensure the pile height is uniform. This step enhances the fabric's smoothness and helps achieve the even texture required for printing. The printing stage applies decorative patterns using techniques such as rotary screen printing or digital printing. The dense, uniform pile of warp-knitted velvet allows for sharp, vibrant prints with precise details, making the fabric visually appealing in furniture applications.

Dyeing and finishing processes further refine Warp Knitting Velvet Print Upholstery Fabric. Heat setting stabilizes the fabric dimensions, while finishing treatments improve stain resistance, colorfastness, and abrasion performance. In some cases, back-coating is applied to enhance stability and durability for heavy-duty upholstery use. These treatments ensure the final product retains its appearance and performance over time.

The loop formation mechanism in warp knitting is distinct from weft knitting. In Warp Knitting Velvet Print Upholstery Fabric, loops are formed in parallel wales, meaning the fabric does not unravel easily when cut. This property allows manufacturers to produce upholstery materials in various widths and shapes without concerns about edge stability. The precise control over loop size, pile density, and surface texture makes warp knitting a preferred choice for high-end furniture fabrics.

Another advantage of Warp Knitting Velvet Print Upholstery Fabric lies in production efficiency. Modern warp knitting machines can produce wide-width fabrics at high speeds, enabling large-scale manufacturing without compromising quality. The process is also adaptable to different yarn types and blends, giving designers flexibility in creating fabrics with varying tactile and visual characteristics.

In practical applications, Warp Knitting Velvet Print Upholstery Fabric is used in sofas, armchairs, headboards, and decorative cushions. Its dense pile and stable structure offer a combination of comfort and resilience, while the printed patterns provide design versatility. The loop formation process ensures that the fabric maintains a smooth surface even under frequent use, making it suitable for both residential and commercial interiors.

English

English 中文简体

中文简体 русский

русский عربى

عربى Español

Español