The processing of solid upholstery fabric involves several steps, each critical to ensuring the fabric's quality, durability, and aesthetic appeal. The process begins with selecting the right fibers, typically cotton, polyester, or a blend of synthetic and natural fibers. These fibers are then spun into yarns, which form the base structure of the fabric. The yarns are woven or knitted using techniques that determine the fabric's texture, strength, and flexibility.

Once the fabric is formed, it undergoes dyeing to achieve the desired color. Solid upholstery fabrics are typically dyed in large batches using either piece-dyeing or solution-dyeing techniques. In piece-dyeing, the fabric is submerged in a dye bath, while in solution-dyeing, the color is added during the yarn-spinning process. After dyeing, the fabric is carefully dried and heat-set to lock in the color and ensure the fabric maintains its shape.

In the final steps of processing, solid upholstery fabric may undergo additional treatments for stain resistance, fire resistance, or water repellency. These treatments are applied depending on the intended use of the fabric. For example, fabrics meant for commercial upholstery may require additional durability treatments to withstand heavy use. Finally, the fabric is inspected for defects before being rolled or packaged for shipment. This entire process ensures that solid upholstery fabric is both functional and visually appealing, making it ideal for a wide range of furniture applications.

Polyester warp knit fabric has found widespread use in various industries due to its unique properties, which include durability, flexibility, and a smooth texture. This fabric is created using the warp knitting technique, where yarns run vertically through the fabric, providing it with greater dimensional stability compared to weft-knitted fabrics. The versatility of polyester warp knit fabric allows it to be used in a variety of applications, from apparel to home furnishings and industrial products.

In the fashion industry, polyester warp knit fabric is often used for activewear, sports bras, and swimwear due to its elasticity, moisture-wicking properties, and quick-drying nature. The fabric's ability to stretch without losing its shape makes it a popular choice for garments that require both comfort and performance. Additionally, its smooth texture makes it ideal for creating garments that are soft against the skin.

In interior design, polyester warp knit fabric is commonly used for upholstery and curtains. Its durability and easy maintenance make it well-suited for furniture that experiences heavy use, such as in commercial settings. The fabric can also be printed on, allowing for a variety of designs and colors to fit different decor styles. Polyester warp knit fabric's ability to resist fading and stretching makes it a reliable option for long-term use in both home and commercial spaces.

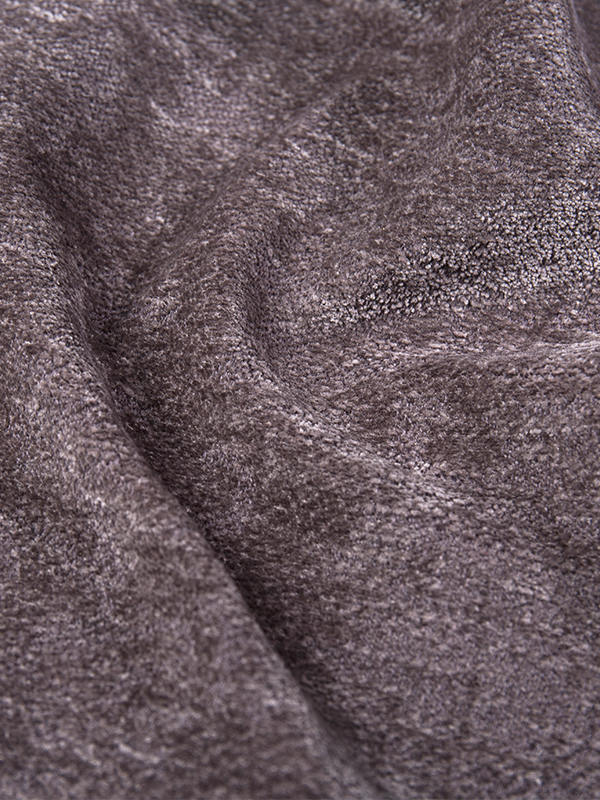

While textured chenille fabric is popular for its rich, soft feel and luxurious appearance, it does come with a few disadvantages that users should consider. One of the primary drawbacks of chenille fabric is its tendency to shed fibers. The fabric's textured surface, created by the unique weaving process, can loose fibers, especially with prolonged use. This shedding can result in the fabric appearing worn or less pristine over time, particularly on upholstered furniture.

Another disadvantage of textured chenille fabric is its susceptibility to crushing or flattening. Due to its raised pile, chenille can lose its plushness in areas that experience frequent pressure or friction, such as armrests or seating areas on couches. This flattening can diminish the overall aesthetic of the fabric, making it appear less appealing after a period of use. Maintaining the fabric's texture often requires regular care, such as brushing or steaming, to restore its plushness.

English

English 中文简体

中文简体 русский

русский عربى

عربى Español

Español