Patterned velvet fabric is renowned not only for its luxurious appearance and texture but also for its specific chemical properties that influence its performance, durability, and care requirements. Understanding these chemical aspects is essential for manufacturers, designers, and end users aiming to optimize the use and longevity of patterned velvet in various applications.

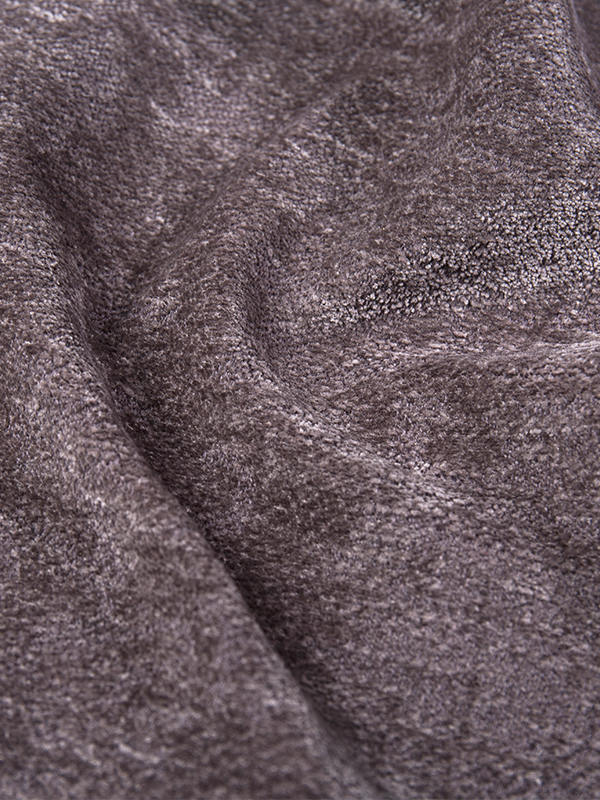

The base fibers used in patterned velvet fabric—commonly cotton, polyester, or their blends—play a crucial role in defining the chemical behavior of the material. Natural fibers like cotton have hydroxyl groups that interact readily with moisture, making the fabric more absorbent but also more susceptible to chemical reactions such as dye degradation or fabric weakening under harsh cleaning agents. Synthetic fibers such as polyester are composed of long polymer chains resistant to many chemicals, providing increased durability and colorfastness. The pile yarns, which form the characteristic soft surface of velvet, are often treated to improve resistance to abrasion and to stabilize the fabric structure.

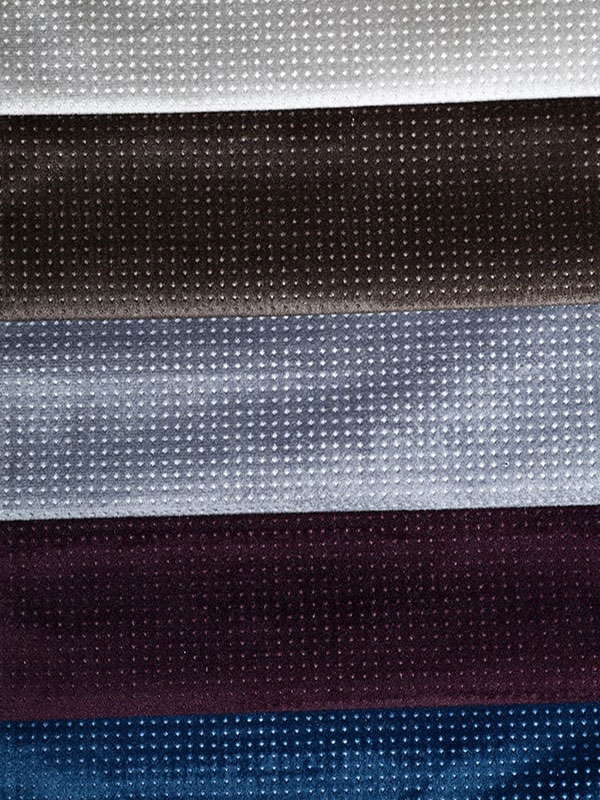

Dyes and pigments used in patterned velvet fabrics are selected to achieve vivid colors while maintaining chemical stability. Reactive dyes, commonly applied to natural fibers, form covalent bonds with the fiber molecules, enhancing wash fastness and reducing dye migration. Disperse dyes used for polyester fibers rely on physical entrapment within the polymer matrix, which also results in stable coloration. The chemical compatibility between the fiber type and dye system determines how well the pattern maintains its clarity and vibrancy over time.

Chemical finishing agents further modify the properties of patterned velvet fabric. Anti-static treatments reduce surface electrical charges, improving comfort and usability. Flame retardants, when applied, must be compatible with both fiber composition and dye chemistry to avoid discoloration or fabric degradation. Water-repellent and soil-release finishes enhance the fabric's resistance to stains and moisture, increasing its suitability for upholstery or fashion applications.

The finishing processes of fashion print leather fabric are a blend of traditional craftsmanship and advanced chemical technology designed to achieve specific aesthetic and functional outcomes. The process often begins with the selection of a suitable leather or synthetic base, onto which print designs are applied using various techniques such as screen printing, digital printing, or embossing.

Chemical treatments are applied to prepare the leather surface, improving adhesion and color reception. These preparatory coatings may include primers or fixatives that enhance the interaction between the print ink and the leather. The inks themselves are formulated to be flexible and durable, often incorporating polymer binders and pigments resistant to fading, cracking, or peeling.

Following the printing stage, finishing chemicals are applied to protect the surface and refine the texture. Clear topcoats or lacquers may be used to seal the design and increase resistance to abrasion, water, and oils. These finishes often include UV stabilizers to reduce color fading caused by sunlight exposure. Additionally, softening agents or plasticizers can be added to maintain the leather's suppleness and prevent stiffness.

Some fashion print leather fabrics receive embossing or texture-enhancing finishes that chemically alter the surface to simulate grain patterns or distressed effects. These chemical processes are carefully controlled to balance aesthetic appeal with the durability required for everyday use.

English

English 中文简体

中文简体 русский

русский عربى

عربى Español

Español