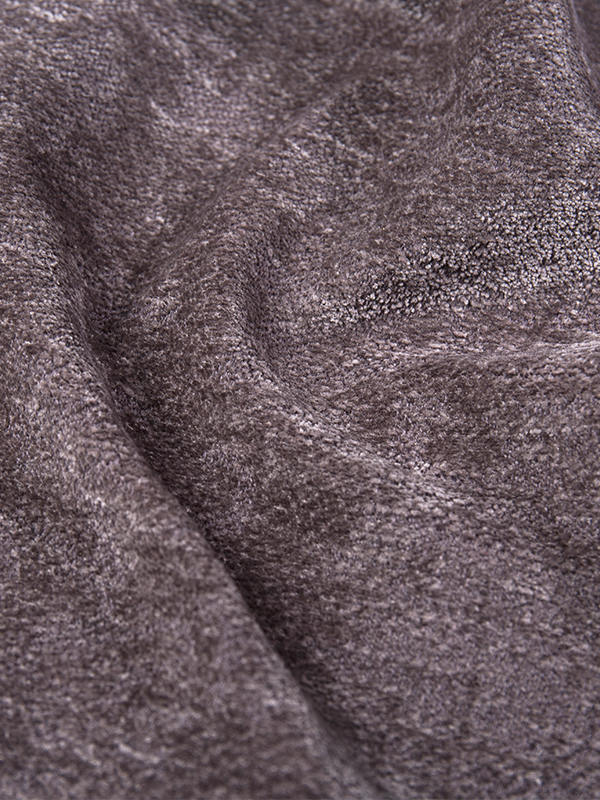

When selecting fabrics for bedding and upholstery, understanding their heat resistance and material properties is essential for ensuring comfort, durability, and safety. Chenille bedspread fabric, known for its soft, velvety texture, is often used to create cozy and inviting bedroom environments.

Regarding heat resistance, chenille fabric is generally made from cotton, acrylic, polyester, or a blend of these fibers, each of which influences how the fabric reacts to heat exposure. Cotton-based chenille tends to have moderate heat resistance; it can tolerate everyday warmth such as body heat and moderate indoor temperatures without damage. However, it is less tolerant of direct heat sources like irons set at high temperatures or open flames, which can cause scorching or fiber weakening. Acrylic and polyester chenille fibers typically exhibit better heat resistance than natural fibers, as synthetic fibers generally withstand higher temperatures before melting or deforming. Despite this, excessive heat can still fiber damage, discoloration, or loss of texture in chenille fabrics. The pile construction of chenille, with its fuzzy surface created by cut yarns, can be particularly sensitive to heat, as high temperatures might flatten or crush the pile, reducing the soft hand feel that is characteristic of this fabric. Therefore, it is advisable to avoid high-heat laundering and ironing procedures for chenille bedspreads and instead use gentle cleaning methods like low-temperature washing and air drying. This approach helps preserve the fabric's texture and appearance over time. Additionally, some chenille fabrics may be treated with flame retardants or heat-resistant finishes, which can improve their performance in environments where heat exposure is more likely.

Chenille fleece knit fabric represents another variant commonly used in blankets, casual wear, and loungewear, valued for its warmth and softness. This fabric combines the plush pile of chenille with the stretch and comfort provided by knit construction, often made from synthetic fibers such as polyester or a polyester blend. The knit structure naturally offers more elasticity and flexibility compared to woven chenille, enhancing wearer comfort and fit. In terms of heat resistance, polyester-based chenille fleece exhibits relatively good tolerance to heat generated during normal use, including body heat and low-level household heating appliances. However, like other synthetic fibers, it is sensitive to high temperatures; exposure to excessive heat can cause melting, distortion, or loss of softness. This sensitivity is important to consider when laundering or using heat-based appliances like dryers or irons. Chenille fleece knit fabrics usually respond well to low to moderate heat in washing and drying, with manufacturers often recommending gentle cycles and air drying to maintain fabric integrity. Additionally, the knit construction facilitates better moisture management and breathability compared to dense woven fabrics, which contributes to overall comfort. Due to its pile surface and knit structure, chenille fleece knit fabric is more resilient to piling and abrasion, making it suitable for regular use in garments and home textiles. Some variants may incorporate anti-pilling finishes or UV stabilizers to extend fabric life and maintain appearance despite frequent wear. Importantly, the balance between softness, stretch, and heat resistance makes chenille fleece knit a versatile choice for consumers seeking both comfort and durability in everyday textiles.

Together, the heat resistance and functional properties of chenille bedspread fabric and chenille fleece knit fabric highlight their distinct applications and care requirements. While both offer appealing softness and warmth, understanding their fiber compositions and responses to heat exposure can guide appropriate maintenance practices. Proper handling ensures these fabrics retain their desirable textures and performance, whether used as elegant bedspreads or cozy fleece garments.

English

English 中文简体

中文简体 русский

русский عربى

عربى Español

Español