The production process of patterned silk fabric involves a series of carefully controlled steps that combine traditional weaving skills with modern manufacturing technology. It begins with the preparation of silk yarns, which are reeled from cocoons, degummed to remove sericin, and twisted to achieve the desired strength and uniformity.

These yarns are then dyed, either before weaving in the case of yarn-dyed fabrics or after weaving for piece-dyed varieties, depending on the intended design. The weaving stage uses either jacquard or dobby looms to create patterns, with jacquard looms being preferred for more intricate and multi-colored designs. In yarn-dyed patterned silk, each color is planned in advance so that the pattern emerges directly during weaving, resulting in clear, well-defined motifs. In printed patterned silk, the base fabric is woven Then subjected to screen printing, rotary printing, or digital printing methods, which apply designs with high precision. After the patterning stage, the fabric undergoes finishing processes such as washing, steaming, and calendaring to enhance smoothness, luster, and drape. In some cases, additional treatments like water-repellent coatings or anti-wrinkle finishes may be applied to improve usability. Throughout production, quality control ensures that the pattern alignment, color accuracy, and fabric texture meet the required standards. The resulting patterned silk fabric retains the characteristic sheen and softness of silk while displaying detailed patterns suited for apparel, accessories, or decorative purposes.

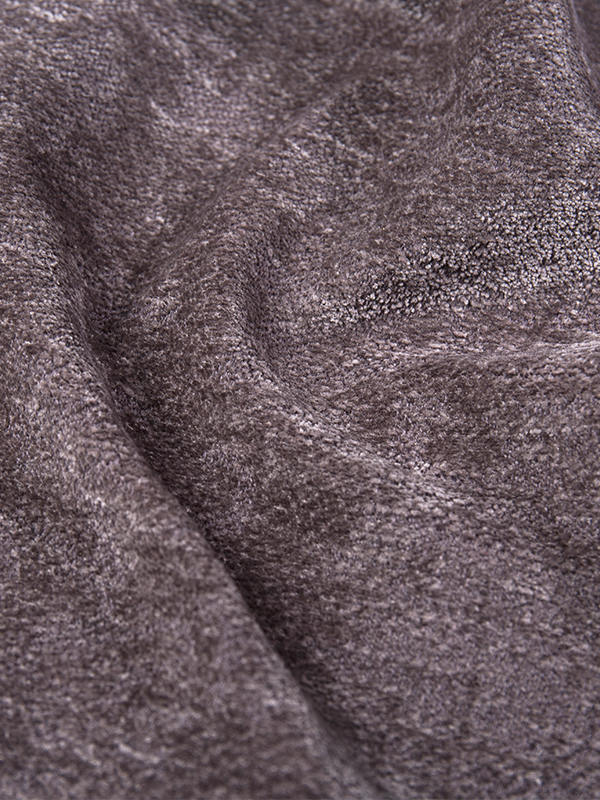

The textile technology of patterned velvet upholstery fabric is designed to create a dense, plush surface with decorative patterns suitable for furniture coverings and interior decor. Production begins with selecting appropriate fibers, which can include cotton, polyester, or a blend, depending on the required durability, texture, and cost considerations. The velvet pile is formed during weaving by creating two layers of fabric connected by pile yarns, which are then cut to produce the soft, raised surface. For patterned velvet upholstery fabric, jacquard weaving is commonly used, enabling complex motifs to be incorporated into the pile structure itself. Alternatively, embossing techniques may be employed after weaving, where heated metal rollers press patterns into the velvet, giving it a dimensional effect. In printed velvet, patterns are applied using digital or screen printing methods, often with pigment or reactive dyes that adhere well to the pile fibers. The fabric then undergoes finishing processes such as steaming to set the pile, brushing to align fibers, and shearing to ensure uniform pile height. For upholstery use, the patterned velvet may also be backed with a secondary fabric to enhance strength and stability, making it more resistant to stretching and distortion during furniture application. Additional treatments, such as stain-resistant coatings or flame-retardant finishes, can be applied to meet performance requirements for commercial or residential interiors. The combination of pile softness, pattern clarity, and durability makes patterned velvet upholstery fabric a favored choice for sofas, chairs, cushions, and decorative panels, where both visual appeal and functional performance are important. The technology behind its production ensures that the fabric not only delivers the tactile comfort associated with velvet but also maintains the structural qualities needed for long-term upholstery applications.

English

English 中文简体

中文简体 русский

русский عربى

عربى Español

Español